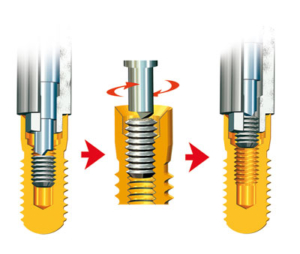

BROKEN SCREW EXTRACTOR KIT

A broken screw fragment inside an implant is a delicate issue to face in the clinic. Counting on the BROKEN SCREW EXTRACTOR KIT system, each type of broken fragment can be removed from the implant if it has not been cemented or if the threads inside the implant have not been damaged in a previous removal attempt. In 90% of attempts the broken screw can be easily unscrewed, but the operation must be completed following precisely the use instructions. The time required to complete the removal procedure may depend on different factors, including the position of the implant which may facilitate or delay the operation.